Customers cover 100+ countries worldwide

Over 40 years of manufacturing and R&D experiences

About WEDO

Tools For Safety

WEDO TOOLS, as an international professional enterprise, specializes in designing, researching, manufacturing, processing and marketing of hardware tools. WEDO develops six main product series, including Beryllium Copper non-sparking and non-magnetic tools, Aluminum Bronze non-sparking tools, Titanium non-magnetic tools, Stainless steel corrosion-resistant tools, VDE insulated tools and industrial-grade steel tools.

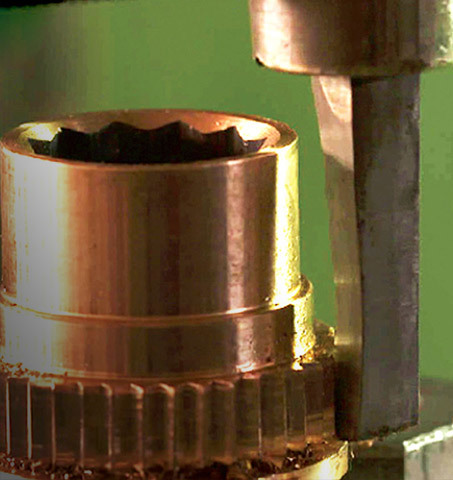

WEDO product lines cover more than 2000 models and over 30000 specifications. Processed by large friction pressing machines of different levels, and adopting the one-time die-forging technology, WEDO tools are completely in accordance with Germany DIN standard, America ASME standard or China GB standard. With a well-developed product quality monitoring system, WEDO also establishes its own physical and chemical analysis center for metallic alloy...

Expertise

Germany DIN standard

America ASME standard

One-time Die Forging Technology

2000+ Models, 30000+ specifications

Innovation

40+ Years of Manufacturing and R&D

10+ Kinds of High Quality Raw Materials

Original Design and Manufacturer

120000 m² Production Area

Annual Production over 30,000,000 pcs

Certification

International ISO System Certified

BAM Certified

CMExC Non-Sparking Safety Tools Certified

CMA and CNAS Certified

Brand

Introduction

WE THE CRAFTSMEN DO SAFETY FIRST

WEDO TOOLS, as an international professional enterprise, specializes in designing, researching, manufacturing, processing and marketing of hardware tools.

View MoreProduct

Knowledge

WEDO develops multiple product series made from different raw materials, including Beryllium Copper non-sparking and non-magnetic tools, Aluminum Bronze non-sparking tools, Titanium non-magnetic tools, Stainless steel corrosion-resistant tools, VDE insulated tools, Industrial-grade steel tools, Tools kits/box/cart, etc.

Beryllium Copper Non-sparking Tools

WEDO non-sparking tools are made of expensive and rare non-ferrous metal in good proportion. They are one-time die forged, with high hardness, strong torque, and completely in accordance with Germany DIN standard. All WEDO non-sparking tools are BAM and ATEX certificated. They are widely used in petro-chemical, oil production, gas production, oil and gas pipelines, power generation, mining, plastics, chemical fiber and other industries.

Aluminium Bronze Non-sparking Tools

WEDO non-sparking tools are made of expensive and rare non-ferrous metal in scientific proportion. They are one-time die forged, with high hardness, strong torque, and completely in accordance with Germany DIN standard. All WEDO non-sparking tools are BAM and ATEX certificated. They are widely used in petro-chemical, oil production, gas production, oil and gas pipelines, power generation, mining, plastics, chemical fiber and other industries.

WEDO brass tools and copper tools are one-time die-forged, completely in accordance with Germany DIN standard. They are widely used in petro-chemical, oil production, gas production, oil and gas pipelines, power generation, mining, plastics, chemical fiber and other industries.

WEDO brass tools and copper tools are one-time die-forged, completely in accordance with Germany DIN standard. These tools are widely used in the mining industry, the maintenance of precious equipment, and other industries. Their advantages lie in durability and reliability, which can meet the requirements of various harsh working environments. Each tool is precisely manufactured to ensure that its performance reaches the highest standards. Thanks to the excellent properties of brass and copper, these tools can still maintain their original quality and performance even after repeated use. Whether in high-temperature, high-pressure, or corrosive environments, WEDO's tools can demonstrate outstanding durability and stability. Choosing WEDO means choosing a high-quality and high-standard work partner.

WEDO titanium tools are high-strength, low-density, corrosion-resistant, and weigh only 50% of steel tools, belonging to the highest level of hand tools. WEDO titanium tools are widely used in aerospace, marine, medical equipment, and places with special requirements for magnetism of tools. They are high-precision tools.

WEDO stainless steel tools are environmental friendly, surface without chrome or other plating. WEDO stainless steel tools are widely used in medical equipment, marine, shipping, petrochemical, nuclear, and food industries etc.

WEDO insulated tools and non-sparking insulated tools are produced according to IEC60900 standard, in accordance with Germany VDE Certification. Before ex-works delivery, all tools must pass 10000V AC. They are Widely used in power maintenance, power station and transmission field, precision instruments, power vessels, automatic switches and other installation and maintenance operations, which can effectively protect workers from electric shock during the use of tools. WEDO insulated tools are single-head structure, exposed metal part should be as little as possible, flange on insulated handle, insulation entirety, no crack or breakage, no joint gap between assembled insulated tools, designed according to manual mechanics, comfortable to hold.

WEDO special jumbo tools adopt 40 chrome steel as raw material in accordance with Germany DIN standard, with good properties such as wear resistance, high strength, etc. They are one-time die-forged, with strong torque, black-spray on surface, beautiful and environmentally friendly. Specifications range from common to jumbo sizes. Ergonomic design, comfort and laboring saving. They are widely used in marine industries, machine manufacture, mining, large equipment maintenance, etc.

WEDO steel tools are made of industrial-grade steel as raw materials, which are suitable for various purposes such as workshops, factories, households, etc. The handles are all ergonomically designed for a comfortable grip and durability. WEDO tools are complete in variety and have superior performance. Depending on the specific properties required for each type of tool, different steel raw materials are selected for production to achieve the best mechanical properties and user experience.

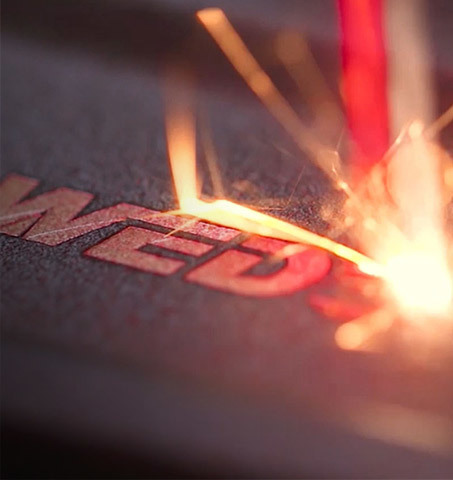

Production

Process

WEDO TOOLS adopts the highest quality raw materials and the most advanced production technology, constantly pursuing technology innovation, improving product structure and internal design, to provide customers with high-quality products with both practical value and appreciation value.

Blog

Center

WEDO TOOLS participates in more than 10 exhibitions at home and abroad each year, including Germany, the United States, Russia, Norway, Dubai, Singapore, Canton Fair and Shanghai International Hardware Show, etc.

07-29

NAICE 2025 – we look forward to seeing you there

How Can We help?

WEDO tools cover customers from more than 100 countries and regions worldwide. To enhance customers' satisfaction, we set up 15 service centers in Germany, Tianjin and Shanghai in China, Russia, Turkey, Serbia, South Korea, Japan, Vietnam, Singapore, India, Canada, Columbia, Argentina, Gabon. Those services center can provide timely post-sales services for our customers worldwide.